Building a smart system to detect non-biohazardous plastic waste from research labs and giving them a fair second chance to be recycled instead of entering a landfill

Type: Studio project at Brown + RISD

My Role: Design Research + Experience Design

Timeframe: 2 months

The Challenge

“Research labs produced 12 billion pounds of plastic waste in the year 2020”

-Earth.org

Literature Review

To comprehensively understand the landscape of plastic waste generation and disposal in research lab facilities, our team undertook a thorough literature review. This involved delving into academic journals, industry reports, and publications related to laboratory practices and environmental impact. We aimed to unearth existing data, trends, and methodologies employed in research labs concerning plastic waste. The review illuminated various facets, including the types and quantities of plastics used, disposal methods, and any existing initiatives for sustainable practices.

Literature Review Findings

Plastic is much more likely to be recycled/down-cycled if it’s sorted really well. This means: plastic types aren’t mixed, and the plastic isn’t filthy

Even if plastics are responsibly separated by lab members, or responsibly sterilized, many recycling plants may still reject it due to uncertainty of contamination

Plastic cannot be truly recycled; the quality of plastic is reduced every time it’s melted.Used plastic is often combined with virgin plastic to form ‘recycled’ products

What we realized was that there is a need for more trust to be established for a recycling facility to be able to accept reclaimed plastic especially from research labs.

Understanding the Challenge Better

“There is often a misguided belief that lab waste simply cannot be recycled because it has been in contact with contaminated, caustic, toxic, or otherwise hazardous materials. However, this is not necessarily true in all cases.”

“Laboratories may lack the resources, processes, infrastructure, or even workplace culture necessary to identify and install waste disposal and recycling strategies.”

“Disposing of components in laboratory products, with some recyclable and others not, can be perceived as demanding and time-consuming in busy lab settings.”

Understanding Plastic’s End-Game

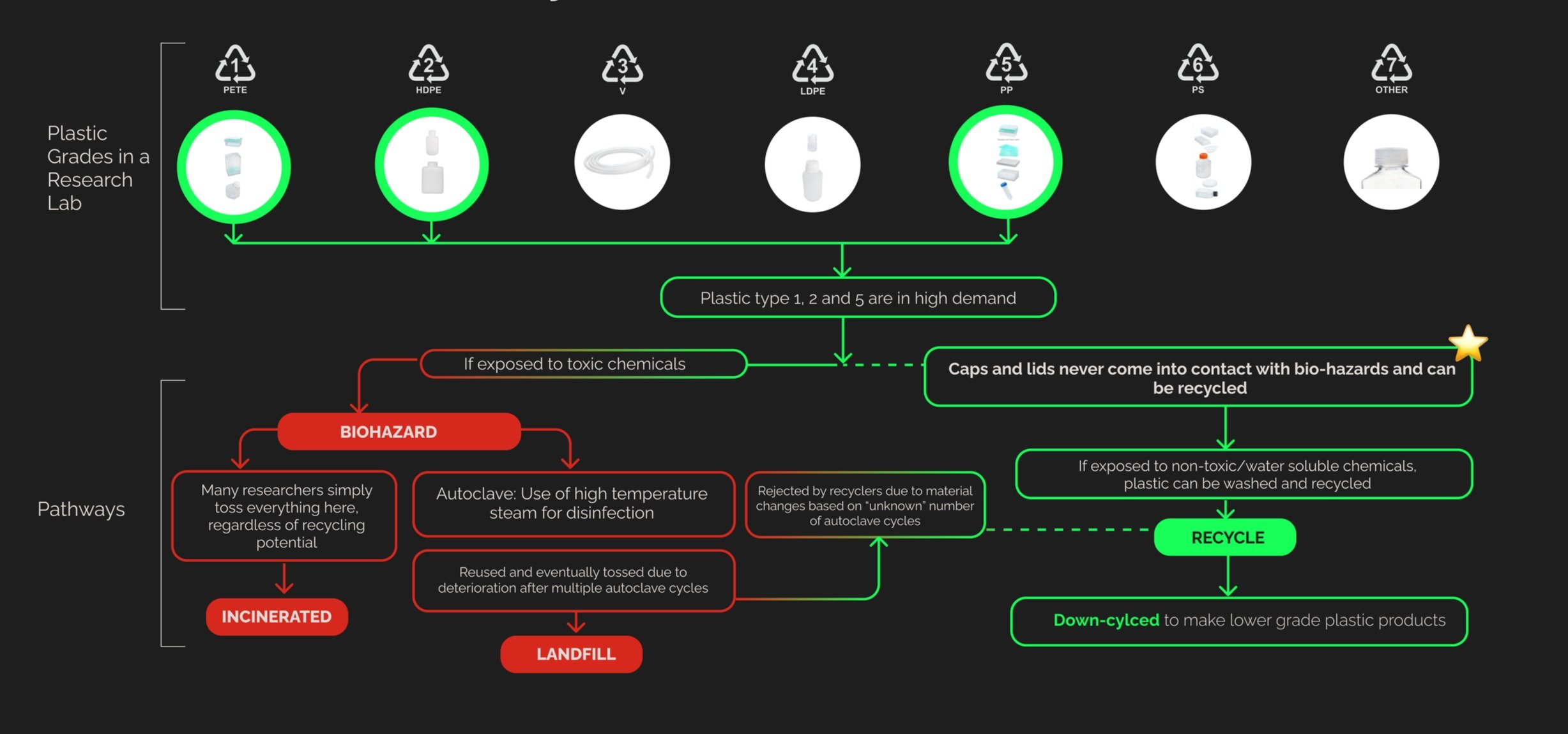

This diagram illustrates the different pathways that plastic waste can take based on the type of plastic and its exposure to various substances. Here's a detailed breakdown:

Plastic Grades Section (Top): The diagram shows the seven standard plastic recycling codes (1-7) with their corresponding plastic types:

Types 1 (PETE), 2 (HDPE), and 5 (PP) are highlighted in green, indicating they are "in high demand" and commonly recyclable

Types 3 (V), 4 (LDPE), 6 (PS), and 7 (OTHER) are shown in gray, indicating they are less commonly recycle.

Biohazard Pathway (Left-Red): This red pathway shows what happens to plastics exposed to toxic chemicals:

Plastics become biohazardous waste

Must undergo autoclave sterilization (high-temperature steam)

Material properties change due to repeated sterilization cycles

Recyclers reject these materials due to unknown degradation

Eventually leads to incineration or landfill disposal

Positive Recycling Pathway (Center-Right): This green pathway shows the ideal scenario for plastic recycling:

High-demand plastics (1, 2, 5) that haven't been exposed to toxic chemicals

Caps and lids that never contact bio-hazards (marked with a star as particularly recyclable)

Plastics exposed only to non-toxic, water-soluble chemicals that can be washed

These materials can be recycled and "down-cycled" into lower-grade plastic products

The diagram highlights a critical issue in laboratory and medical waste management: many researchers dispose of all plastic waste as biohazardous regardless of actual contamination, leading to unnecessary waste of recyclable materials. The diagram advocates for better segregation practices to maximize recycling potential while maintaining safety standards.

Common lab products that can be recycled

Pipette tip boxes, plastic beakers, and flasks: usually made of easily recyclable plastics like polycarbonate and polypropylene.

Petri dishes and culture plates: by implementing a proper disinfection process, these products are usually quite easy to recycle.

Recycling thin plastic packaging in labs reduces thousands of pounds of waste/year.

Subject Matter

Expert Interviews

We conducted interviews with people working in research labs, pHD students, research students and even a specialty recycler in Boston focusing on plasticware leaving research facilities.

The experts we spoke to-

RESEARCHERS

To understand current workflow and recycling practices

Alec Mccall

Biomedical Engineering, Brown University

PhD Student, Shukla Lab

Sarah Planchak

Biomedical Engineering, Brown University

PhD Student, Tripathi Lab

Dr. Ipsita Pand

Anatomic Pathologist

RECYCLERS

To understand a recycling facilities structure and needs

Serena Monteiro

Green Labs Recycling- Business Operations and Recycling Coordinator

Leo Kobayashi, MD Professor of Emergency Medicine— Project: “Recycling PLA filament at Brown University’s Design Workshop”

ENGINEERS

To understand what technology we can use to solve this problem

Josh Lamstein

Gladstone Research LabsSoftware EngineerMachine Learning

Sweekriti Satpathy

Microsoft, Principal Software Engineer

Siva Kumar

AI and Technology Entrepreneur

What we heard from the Experts

We conducted interviews with people working in research labs, pHD students, research students and even a specialty recycler in Boston focusing on plasticware leaving research facilities, as highlighted above.

Here’s what we found-

Everything needs to be sterile which is why plastic is prevalent and often single use.

In the labs – plastics are sorted as trash, recycling, sharps and biohazards. There are no recycling bins for lab work. Paper and cardboard is recycled, but the plastics are tossed as biohazard.

“You don’t let things accumulate, toss immediately”

“No one wants to do research with reused materials. It can mess up results”

Rapid Ethnographic Study

Conducting a rapid ethnographic study at Brown University's Shukla Lab was vital for delving into the nuanced dynamics of the lab environment, especially regarding the usage and disposal of plastic materials. Ethnography provided unique insights through immersive observation and participant engagement, unveiling implicit patterns and behaviors among lab researchers. This understanding was pivotal for formulating targeted interventions to address plastic waste generation and promote sustainable laboratory practices.

Trojan Horse Finding

We found that researcher’s add tape to a lot of their equipment for labelling and tagging!

This got us thinking—What if we use the very labels that scientists use to tag things in the lab as a tag to sort plastic lab waste for a material passport?

The Solution

We decided to make a label maker that works with a robotic arm sorter at the recycling facility!

Labels were already an integral part of the workflow, so we used this as a base for the solution over which we innovated to incorporate a “Material Passport”

The Material Passport allows for us to include all the information about what the plastic was exposed to prior to tossing and increase transparency for the plastic trash collection and sorting process

The Labels and the Label Maker

Each label is color coded to depict what kind of plastic type it is- red is grade 2 HDPE, blue is grad 5 PP and green is grade 1 PET. The label comes with a QR code which when scanned gives you the “Material Passport” as seen below.

Each QR code from the label takes you to a “Material Passport” that gives you information on all the chemical or physical agents that the plastic apparatus has come in contact with.

Leveraging Google’s Teachable Machine, we trained a lightweight computer-vision model sample labels, teaching it to recognize subtle variations in shape, typography, and hue. Once deployed, the system instantaneously captures each label as it passes under the camera, classifies it with over 95 percent accuracy, and flags the dominant color—red, blue, green, so our downstream sorter knows exactly which bin to send it to.

This automated color identification eliminates manual inspection, accelerates throughput, and frees staff to focus on higher-value tasks such as quality checks and exception handling.

Below is a model of the label maker that prints the stickers out. It has a screen and works like a mobile printer would. The clasp at the back lets you clasp it to tables and desks for easy access.

Label Maker “In-Action”

This is the software system we designed that would be integrated with the label maker to facilitate adding the agents that the plastic apparatus comes in contact with so that the QR code can be automatically updated with that information and also of-course to facilitate printing the labels to mark the apparatus before a scientists starts a protocol or experiment.

Robotic Sorting “In-Action”

We simulated a robotic arm sorter that detects the color of the label on the plastic apparatus to sort the different grades of plastic out using a color tracking algorithm.

Tying the whole service together

Creating this system was complex, with different arms that needed different kinds of design love. This service map was created to simply the process for our own understanding so we could see what system fit in what part of the process and in what capacity.

Final Thoughts

Recycling (or down-cycling) isn’t going to fix the climate crisis or make planetary resources infinite.

Reducing is much more impactful than recycling. Labs around the globe need to build systems that accommodate scientific progress built on sustainable practices.